Here’s the parts list for my DIY grow light. I’ll try to include links when I can so you can more easily source the parts you need.

Heat sink

- 40x40x3mm C channel aluminum profile – 8x 83cm

- 4x12mm machine screws, 4mm nuts and washers for holding the heat sink together

LEDs

- 36x Deep red Led, 660-670nm

- 16x Red Led, 620-630nm

- 18x 3w Royal Blue Led, 445-450nm

- 8x Blue Led, 460-470nm

- 4x Constant current driver, good for 10-18 LEDs

- I am also using one of these: 670mA 36W Constant Current LED Driver

- 200x 60 degree lenses for Leds

- 1x Thermal adhesive $4.79

- I used this one from dealextreme, but it’s handy getting everything from satisled

I’ll add more things to this list as the build goes on and I think of more things that I forgot.

After finishing the heat sink for the LEDs next matter on hand was deciding on what LEDs to use and how to spread them on the heat sink for even light distribution.

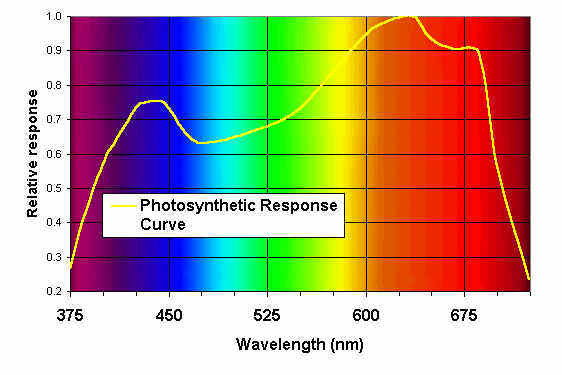

First off was the matter of selecting what wavelength I wanted the lights to cover. I did some googling and found a few discussions and graphs on what frequencies of light plants pick up. I ended up on pages detailing Chlorophyll-A and Chlorophyll-B uptake and other fancy words I cannot remember. I also came across a few graphs like this one

What this graph is saying is pretty much what light spectra plants actually use. Pay special attention to the peak at ~445nm and ~630nm. Because of this and other research this is the distribution I settled upon:

36x Deep red (660-670nm)

16x Red (620-630nm)

18x Deep blue (445-450nm)

8x Royal blue (460-470nm)

But how should the LEDs be distributed on the heat sink to spread the different spectra of light evenly? I fired up libreoffice and gave the layout a shot:

I wasn’t completely happy with any of these layouts, so I gave google sketchup a try

Much better! Horizontal spacing between the LEDs is about 85mm (center to center). I will be using 60 degree lenses to disperse the light in orderly fashion. I then did some basic trigonometry calculations (which I had completely forgotten about how to do) and I came to the conclusion that when the light is suspended about 30cm above the plants each LED will overlap 2 leds on each of its side (horizontally). That should blend pretty nicely and I’m looking forward to turning this thing on and seeing the result of my work.

I still haven’t told you what plants I’ll be growing – Do you think it’s weed?

Next post will detail how I attach the LEDs to the heat sink.

I’ve sourced parts and information for my DIY LED grow light for the past few weeks, and it’s starting to come together. I will be writing a few posts on the build, this one being about cooling and mounting of the LEDs

For cooling I decided to use 40x40x3mm C aluminum profile. It’s 3mm thick and should offer plenty cooling for the LEDs.

I went to a local metal supplier and bought 2x 6m long profile and had them cut it down in 83cm bars.

This is what it looked like when I arrived home

Then there was the matter of cleaning the profiles since they had a lot of cutting oil on them. A little white spirit and a few tissues and that issue is solved.

Next issue is how to fasten them together. I decided to bolt the profiles together. That meant drilling holes into the profiles, making sure to perfectly line the holes up so everything fits together nicely:

Then bolting them together

What I ended up with is a 83x32cm heat sink that will hopefully cool the LEDs effectively.

In the next post I will be detailing what kind of LEDs I’ll be using, how many and the distribution of them on the heat sink. A seemingly easy task that took me way longer than I thought it would.

I recently started acquiring everything I need to be able to slant and propagate yeast. I’ve never used liquid yeast before, so the first order of business was building a stirplate to be able to step up slants and make starters.

Stuff you need

- A fan – Many people use 12v 120mm or 80mm computer fans

- 1 or 2 strong magnets. I used one from an old hard drive, and some epoxy to attach it to the fan

- 12v power supply (wall wart) Make sure it is at least 500mA, preferable 1A

- Project box – make sure it’s large enough to hold the fan + components. You can get a cheap tupperware box from somewhere, or you can go fancy and buy an electrical box from eBay or radio shack.

- For the speed controller:

- Potentiometer, 1k resistor, 1uF electrolytic capacitor, 0.1 uF ceramic capacitor, protoboard, LM317 voltage regulator

- You’ll also need some tools to assemble everything, f.e. soldering iron, drill, screws, glue and a few screws

Let’s start with the speed controller

I followed the instructions from here to arrange the components on the strip board. In retrospect I should probably have gone with a PWM speed controller in order to have greater flexibility with setting the speed. Maybe next time.

As for assembling everything in a project box, a picture is worth a thousand words:

<pic here>

Depending on what box you will pick your mileage may vary.

Next on my yeast propagation todo list

Before I’ll be able to make yeast slants I have a few more things I need:

- Buy a pressure cooker to sterilize everything, including yeast slants

- Buy some yeast to use. I’m thinking I want to do a wit beer, some kind of belgian trappist and more. There are no home brew stores in Iceland that sell liquid yeast, so I will have to order from abroad and cough up some cash for express shipping and cold packs

Update: A lot of people on reddit have voiced concern about using plastic for boil kettles, even going as far as calling me a Darwin award nominee and saying this is dangerous and stupid. I assure you that if you do as I did and pick a proper bucket that is manufacturer rated for high temperatures for extended amount of time then you will be fine. I have used and built more than 10 of these buckets and used for more than a year for countless brews without any incident. Just be smart and don’t try moving a bucket with 25 liters of boiling liquid – You’re gonna get burned!

I’ve gotten a few questions about the boil kettles I use for my brewing endeavors. So here’s short writeup on how I make them.

I use a plastic fermenting bucket for the kettle. Plastic is actually very handy for this type of operation, being really cheap and readily available. The only drawbacks I can see is that it won’t last as long as a stainless or aluminum kettle, and with time the plastic will suck up some color from the wort. The large upside however is that this is a lot cheaper than most (all?) options I can think of and will last a long time.

Step 1 – Disassemble the kettles

Acquire a couple of electric kettles with removable elements. Disassemble and remove the elements.

Remove some screws or break plastic to get to the actual heating element. Don’t worry about breaking the housing, you’re going to throw it away after disassembling the kettle.

This is what you should end up with – a heating element and a silicone gasket. Make a mental note of which side of the gasket is out and in. Also note which screw goes where, along with the washers.

Step 2 – Drill holes for the heating elements

Source a plastic container of the size you want. I use a 33 liter fermentation bucket that’s rated for temperatures up to 130°C and is food grade. It’s handy if the bucket is see through with a scale, but not necessary.

Measure the size of the hole for the heating element(s) and drill a hole for them in the bucket. Most chinese made electric kettles have these same elements, and a 38mm hole saw is perfect for them. The hole saw will leave the hole a bit rough, so clean it up with a little sandpaper or a knife when done drilling.

Step 3 – install elements

Put the gasket(s) in the hole, then assemble the element and element backing in the hole. Don’t over tighten the screws – You can get away with surprisingly little tension because of how well the silicone gasket fits.

Step 4 – Leak test

Fill the boil kettle with water to check for leaks. If it leaks then tighten the screws and/or check if the gasket is seated properly.

Step 5 – Make beer!

You can connect the heating elements with this kind of connector. It’s the same connector as is used on computer power supplies. It’s cheap, available in most electronic and computer stores. You might even have a few lying around the house.

You can connect the heating elements with this kind of connector. It’s the same connector as is used on computer power supplies. It’s cheap, available in most electronic and computer stores. You might even have a few lying around the house.

You can use the kettle for just heating sparge water, boil water or whatever else you would use a “normal” kettle for. You could probably use it as a cheap turkey boiler if you like.

I hope this post proves useful for someone – If you have any questions or comments then please comment.

I get a lot of beginner brewers asking me how they can get started brewing all grain for the least amount of money and equipment possible. For those people I have devised a start kit with everything you need for all grain brewing with the least amount of money possible (in my opinion). And just because the kit is simple you don’t sacrifice quality of the finished product.

The process I recommend starting out with is Brew in a Bag (BIAB).

Before I go into the BIAB process I want to detail what I include in the BIAB start kit I make for newbies:

- 33 liter plastic boil kettle, with 2x 2200 watt heating elements from electric kettles

- 33 liter fermentation bucket with an air lock

- Polyester fine mesh bag big enough to cover the inside of the boil kettle (grain bag)

- Thermometer (digital)

- Hydrometer

- Racking cane

- Chlorine based cleaning agent

- Iodophor for sanitizing

- 70 bottle caps

- Capper

- Your first all grain recipe – Milled grains, hops and dry yeast

I have written an exhaustive document detailing the process using this kit. It is however in Icelandic, but I intend to translate it to English soon™.

For starters I will just give a quick summary of the process:

- I start out by heating up 27 liters of water in the boil kettle to 72 degrees celsius (161F)

- I put the grain bag in the boil kettle and add the grains, taking care to stir well to avoid any clumps in the mash

- By now the temperature should have dropped to 67-68°C (15-154F) so I put the lid on the kettle and cover the kettle with towels to keep the temperature stable for the next 60 minutes. This process is called mashing and it is very important to keep the temperature stable.

- After 60 minutes I uncover the kettle, raise the bag off the heating elements and raise the heat to 77°C (170F) for 10 minutes

- After 10 minutes at 77°C (170F) I hoist the bag up and drain the remaining liquid from the grains. I use the time while liquid slowly drips from the grains to turn on both heating elements.

- When most of the liquid has drained from the grains I throw the grains away*.

- When the liquid (wort) has reached boiling I disconnect one heating element as one is enough to keep a vigorous boil. I boil for 60-90 minutes depending on recipe and add hops and other additions as the recipe states.

- After the 60-90 minute boil I stop the boil, put a sanitized lid on the boil kettle

- After about 24 hours the wort has cooled down to 20-22°C (68-72F) and I pour everything except the sludge on the bottom of the boil kettle into a sanitized fermentation bucket. Some splashing is encouraged here, as it will oxygenate the wort and help the yeast get started. I take a sample of the wort and measure it with a hydrometer.

- I add the yeast to the fermentation bucket, put the lid on and the airlock into the hole on the lid.

- After about 10 days the fermentation is finished and the beer is ready for bottling (which I’ll describe in another article)

* You can also make bread, dog treats or feed the spent grains to animals.

It is extremely important that everything that touches the beer after boil is properly sanitized and cleaned!

This is the short version of how a typical brew day using BIAB goes. If someone wants I can translate the full document to English and post here. I realize that some people will disagree with some of the processes described here (no chill, no sparge etc) but this is a great, simple way to get started with all grain brewing, and these techniques can be extended and improved upon with more equipment after a few batches. This will make a perfectly good beer that can stand comparison to beers brewed with equipment costing many times more.

I hope this article has proved useful for someone, and if you have any questions the please comment and ask away!

Here’s my kegerator. I scored the refrigerator very cheap from a local classifieds site and the kegs and parts I got from kegconnection.com. I can see myself drinking a lot of beer the first days after getting this one into operation. One needs to be perfectly sure everything is in order! And what better way of making sure everything works than pouring a pint?

I’ve been working on a single vessel brewing system, strongly resembling the one sold be speidel, called braumeister.

Some progress has been made already, and I hope to be able to brew using this system soon.

Short version of what happens in this system: The system consists of two vessels, one 33 liter vessel and another 20 liter vessel with a false bottom.

The larger vessel has heating elements controlled by a PID temperature controller. The smaller vessel sits in the larger and holds grains during mashing. Water is circulated through the grains during mashing to keep temperature even and allow for step mashing. After mashing I remove the vessel and drain it into the larger vessel, where the wort is boiled.

This is my mash tun. It’s a 20 liter plastic bucket and I cut the bottom out of it and put in a fine mesh stainless steel net. During mashing it will hold all the grains, with a pump circulating water through the grains and keeping temperature stable.

This is my mash tun. It’s a 20 liter plastic bucket and I cut the bottom out of it and put in a fine mesh stainless steel net. During mashing it will hold all the grains, with a pump circulating water through the grains and keeping temperature stable. This is the inside of my boil kettle. Visible are 2x2200w heating elements, pump inlets and outlets and a pt100 temperature probe. The probe and elements will be connected to a syl-2362 PID controller from auber instruments.

This is the inside of my boil kettle. Visible are 2x2200w heating elements, pump inlets and outlets and a pt100 temperature probe. The probe and elements will be connected to a syl-2362 PID controller from auber instruments.I brewed a 20 liter batch of this on february the 11th. This is one of the tastiest APAs I’ve brewed so far. Mashed at 67°C in a polyester bag. OG 1.056

I’ve brewed using the BIAB method for a few batches now and I must admit that I’m hesitant to do anything else – Being able to brew a beer in about 3 hours, as opposed to at least 4-5 hours using traditional mashing techniques definitely makes me want to brew more often.

4.10 kg Pale Malt (Weyermann) (3.3 SRM) Grain 75.16 % 0.90 kg Vienna Malt (Weyermann) (3.0 SRM) Grain 16.50 % 0.23 kg Caramunich I (Weyermann) (51.0 SRM) Grain 4.22 % 0.23 kg Carahell (Weyermann) (13.0 SRM) Grain 4.13 % 25.00 gm Amarillo [9.00 %] (60 min) Hops 25.4 IBU 15.00 gm Amarillo [9.00 %] (30 min) Hops 11.7 IBU 13.00 gm Amarillo [9.00 %] (15 min) Hops 6.6 IBU 18.00 gm Amarillo [9.00 %] (5 min) Hops 3.7 IBU 1 Pkgs US-05 (DCL Yeast #US-05) Yeast-Ale

This is a slight variation of this recipe. I traded the cascade hops out for Amarillo and added more pale ale malt to give the beer more kick.

I’ve looked at these quick disconnects from colder for my single vessel brewing system. They look perfect, even have a valve built-in so when I disconnect they automatically close the flow. I shall try to update this blog when I get them.

Also on my to-do list for this blog: Add details of my single vessel brew system.